Conçu avec précision pour l'excellence textile

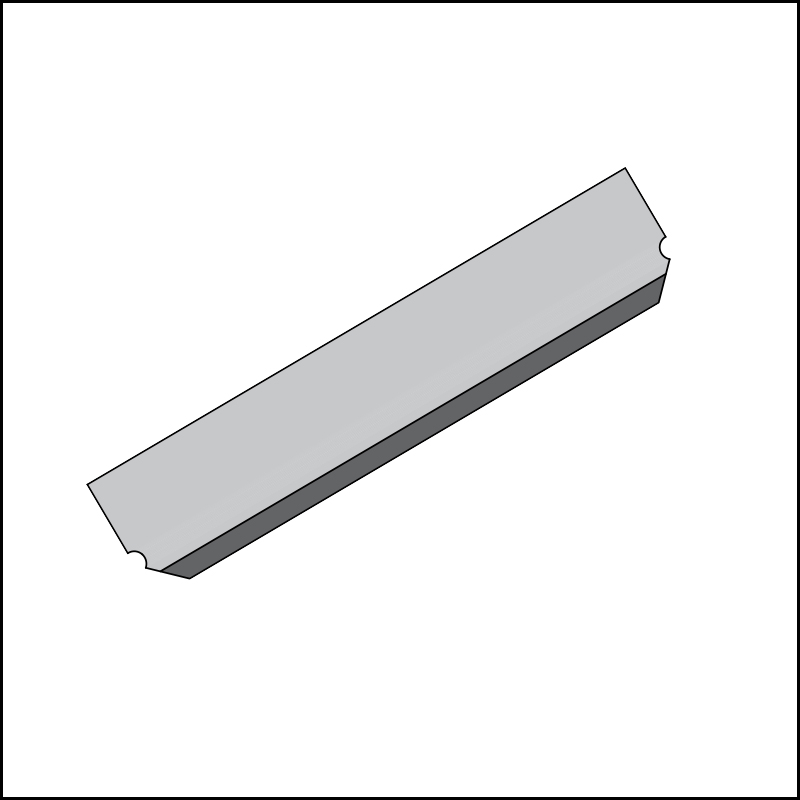

Precision Engineered for Textile Excellence: The Meirente MRT-A178 Staple Fiber Blade

In the demanding world of industrial textile processing, cutting precision directly impacts product quality and production efficiency. The Meirente MRT-A178-15.8-09 Staple Fiber Blade exemplifies the engineering rigor required for high-performance staple fiber processing, combining exacting dimensions with tailored material solutions.

Technical Specifications & Design Philosophy

Dimensional Precision: 178mm (L) × 15.8mm (W) × 0.9mm (T) – optimized for integration into high-speed cutting machinery while maintaining rigidity.

Material Science: Dual-phase construction using stainless steel for corrosion resistance and hard metals (likely tungsten carbide or tool steel) for edge retention, balancing longevity with cutting aggression.

Geometric Optimization: The 15.8mm width enables consistent fiber bundles cutting at ±0.1mm tolerances, critical for uniform yarn production.

Performance Advantages

Fiber-Specific Engineering:

Maintains sharpness through synthetic polymer (polyester/nylon) and natural fiber (cotton/wool) processing.

Reduced friction design minimizes heat buildup during continuous operation.

Durability Enhancements:

Hard metal components resist abrasive wear from silica-rich natural fibers.

Stainless steel substrate prevents chemical degradation from dye residues.

Customization: Addressing Industry Pain Points

Meirente’s core competitive advantage lies in its dddhhhone-stop non-standard customizationdddhhh:

Blade Geometry Adaptation: Modifying width (12–25mm), thickness (0.6–1.5mm), or edge angles for specialized fibers.

Material Re-engineering: Adjusting steel hardness (HRC 58–62) or coating selection (DLC/TiN) for specific wear conditions.

Rapid Prototyping: Accelerated production cycles for trial blades within 72 hours, enabling process optimization.

Industry Applications

Synthetic Fiber Lines: Precision cutting of polyester tow for filling materials

Recycled Textile Processing: Maintaining edge integrity when cutting blended reclaimed fibers

Nonwoven Production: Consistent staple length control (±1mm) for uniform web formation

Why This Matters for Manufacturers

In textile operations where blade failure causes:

↓ 22% production efficiency (downtime for replacements)

↑ 15% material waste (inconsistent fiber lengths)

The MRT-A178 platform delivers:30% longer service life vs. generic blades

5–8% improvement in cut uniformity

Seamless integration into automated lines like Truetzschler or Rieter systems